Refrigerated Centrifuge

| Healthcare Products | Refrigerated Centrifuge

NEW KBM 90 Plus – Blood Bank Centrifuge Available Now – Click Here to Download Brochure

KBM 80 Plus is the new generation microprocessor controlled blood bank centrifuge with forward thinking design and technology. Ideally used for centrifugation of whole blood for components separation like packed red cells, platelet rich plasma, platelet concentrate, cryoprecipitate and buffy coat etc.

Advance manufacturing techniques are used for mounting of brushless induction drive motor in PUF insulated, corrosion free, stainless steel armored chamber, resulting in minimized vibration and noise level. The smooth acceleration / deceleration helps in clear separation thus ensuring high quality component yield.

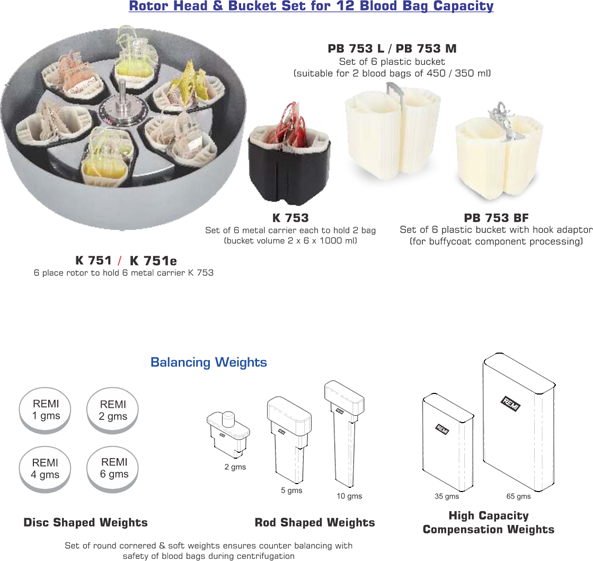

This centrifuge cater to the requirements of small, medium & large blood centers with flexibility to choose from 3 rotor options. The rotors are designed to accommodate specific type of oval shaped metal buckets & plastic carriers for holding six, eight & twelve blood bags of different volumes & configuration like 350 ml / 450ml, double / triple / quadruple, penta bags & inline-filter (quintuple) blood bags.

User-friendly software & controls helps in ease of operation. There is a unique facility for setting & controlling the centrifuge run either by RPM (speed) or RCF (g force) thus eliminating the need of manual calculations. Interactive menu driven program guides the operator through the setting process of run parameters & also the operational status while centrifuge is running.

Specially designed wind shielded rotors reduces friction which helps in energy saving & better temperature management. Advanced imbalance sensor neutralize 90g loading imbalance.

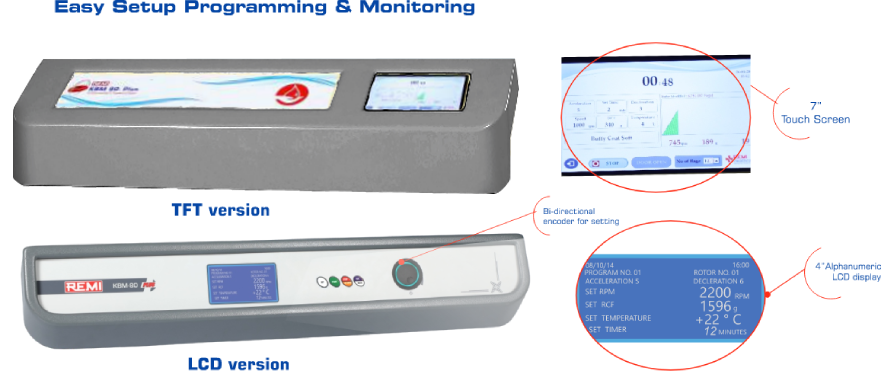

KBM BO Plus comes with 2 variants

- 1.LCO Version

- 2.TFTVersion

Additional Features of TFT VERSION

- Facility to set multiple user profiles with password protected access

- Protected admin control for key parameters

- Display of realtime run graph with display set & run parameters

- Gloves friendly touch screen operation with option to connect with wireless mouse

- Sequential program with speed & time triplets

- Inbuilt Rotor & Bucket cycle counter to notify user for replacement

- Flexible timer option to display total run time with / without acceleration

- Onscreen manual, troubleshooting & process guide Enables remote monitoring with casting live screen on

mobile phone (optional)

Performance

- Speed holding accuracy +/- 10 RPM

- Multiple acceleration & deceleration profiles

- Temperature range from -20°C to +40°C

- Low noise level (≤ 55db)

- Choice of 3 wind-shielded rotors to process 6, 8 & 12 blood bags per cycle

- Tropicalized to run from 0°C to 40°C & RH up to 95%

Leading Technology

- Brush-less induction motor with frequency drive, practically maintenance free

- Advanced user friendly microprocessor control

- Programmable centrifugation parameters for accurate control

- Onboard real time user data log in with password protection

- Dedicated software for data analysis / PDF Reports, connectivity with RS 485/USB

- Auto-adjustable effective centrifugal force irrespective of rotor load

User Friendly

- Facility to set and indicate RPM or RCF

- Simultaneous display of set & run parameters

- Self-diagnosis of program errors

- Microprocessor controlled automatic lid opening with touch button

- Log of 50 run records for LCD/1000 run records for TFT version

- Display of real time & Date

- Castor wheels with floor standing jacks for vibration free run

- Emergency lid opening provision in case of power failure

- Auto compressor cut off on lid opening

Safety

- Automatic lid interlocking and unlocking

- Imbalance cut-off with indication for major variation beyond 75-100 gms

- Safety key lock to prevent unauthorized use

- Rotor over speed protection

- Alarms for imbalance, lid open, over temperature

- Password protection for authorized access

- Tamper proof memory & last program retell

- Automatic Rotor identification & indication

- Automatic recovery of process in case of power interruption “Catch On Fly”.

Data Acquisition System

These centrifuges have inbuilt system to collect & store all data related to centrifugation process like operator code, process type, time, temp, RPM, RCF, acceleration, deceleration & process status etc. The data from the centrifuge can be transferred to a computer using a data interface. This data can be used by blood centers for quality analysis & control.

Customized Software for Data analysis

ModelCIS-18 Plus

| Technical Specifications | |||

| Parameter | Unit | KBM 80 Plus | |

|---|---|---|---|

| LCD Version | TFT Version | ||

| Process controls | Type | Bi-directional encoder | HMI Touch Screen |

| Menu driven program | Nos | 99 | 400 |

| Acceleration profile | Steps | 1 – 9 | 1 – 15 |

| Deceleration profile (incl, coasting) | Steps | 1- 10 | 1 – 15 |

| Max. speed | RPM | 4200 settable ±10 RPM | 4200 settable ±10 RPM |

| Max. RCF | g | 6000 | 6300 |

| Max time | hh:min | 0 to 99 hr 59 min | 0 to 99 hr 59 min 59 sec, Hold function |

| Compatible Rotors | Code | K 711/M, K741, K751 | K 711e/M, K741e, K751e |

| Dimension ( W X D X H) | mm | 840 X 940 X 950 | |

| Compliance | IEC 61010-1:2016, EN 60601-1,EN 60601-1-2, CE, US FDA | ||

Supply : 220-240 volts, 50Hz, Single phase

REMI KBM 80 Plus meets the component separation guidelines by AABB & DGHS

| Important Parameter for Quality Components | Procedural Requirements (as per AABB & DGHS manual)* |

Technical Features KBM 80 Plus |

|---|---|---|

| Centrifugal Force (RCF) | 5000 g Heavy spin – Max. RCF |

Up to 6000 g / 6300g |

| Temperature Range | Need temperature 22°C±2°C to run PRP method & Buffycoat method & 4°C to run FFP & Cryoprecipitate method |

Achieves both desired temperature of 22°C & 4°C with accuracy of ±1°C along with setting range of -22°C to ± 40°C |

| Calibration | Must be calibrated for speed & Time for various component preparation |

Special eyelet window for quick calibration |

| Imbalance | Contents in opposing cups must be equal in weight to improve centrifuge efficiency |

Imbalance Cutoff with indication to ensure component quality as well as safety |